Microfocus Rod Anode X-ray Tubes

Testing circumferential welds of aircraft parts or heat exchangers often requires special rod anode X-ray tubes with panoramic exposure. X-RAY WorX designs and manufactures application specific rod anode tubes with different beam geometries, diameters, and lengths.

Product lines of rod anode X-ray tubes

Product lines of rod anode X-ray tubes: RA, RAC, RAC Superfocus

Highlights of the rod anode X-ray tubes

-

- High resolution digital and great flexibility digital radiography (DR) applications in automotive, energy, and aerospace industries according to

EN 17636-2. - Special reflection targets for application of digital flat panel detectors according to

EN 17636-2. - Panorama targets are available for film (RT), and computed radiography (CR) applications.

- Flexible rod anode solutions with up to

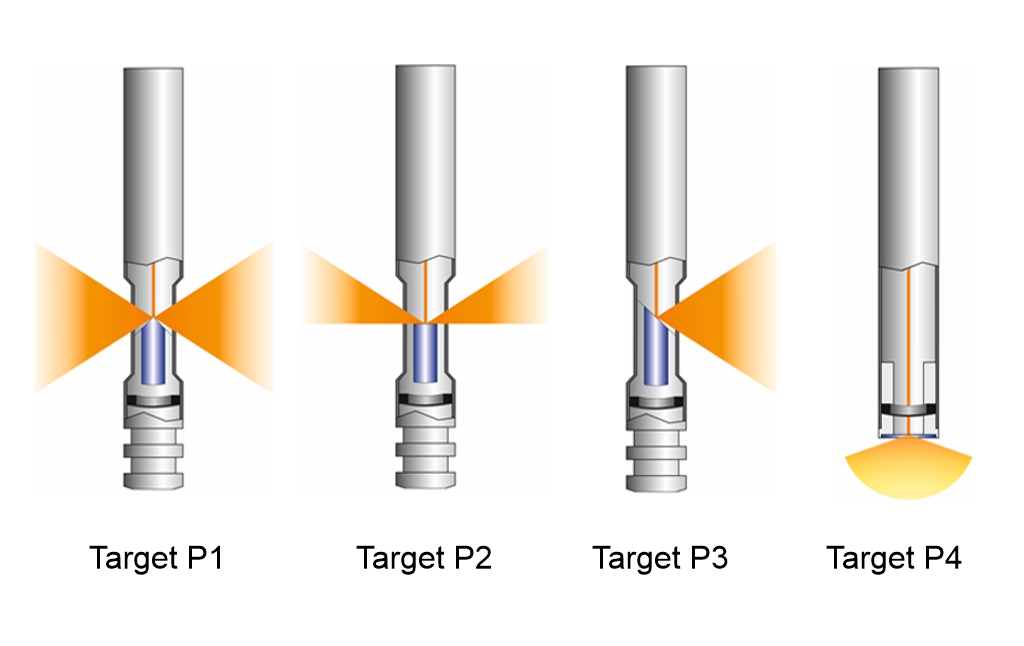

1.5 m length. - Exchangeable tube heads with panoramic, reflection, or transmission target.

- High resolution digital and great flexibility digital radiography (DR) applications in automotive, energy, and aerospace industries according to

Aerospace industry

Energy industry

Process industry

Pipe inspection

Casting industry

Railway industry

Fields of application for rod anode tube

-

- Mechanical components

- Circumferential electron beam (EB) welds

- Rotor blades, turbine blades, aircraft turbines

- Electronic assemblies, sensors, actuators

- Titanium and aluminum castings

- Composite materials, bi-metal pipes

- Wind power stations

- Pressure vessels, gas turbines, tanks, valves, and flanges

- Tube-to-tube-sheet welds of heat exchangers

- Circumferential weld seams

Product line RA

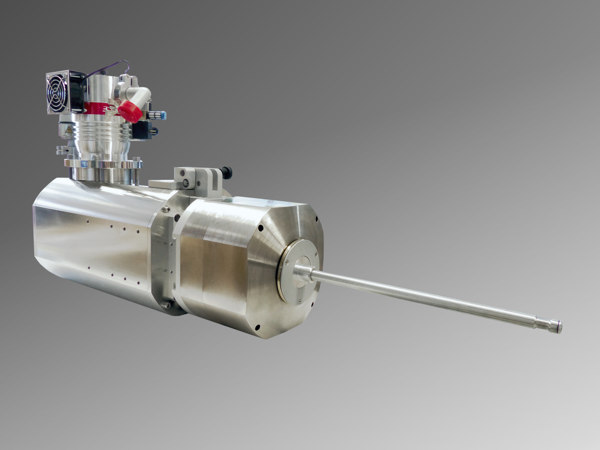

Microfocus X-ray tube XWT-225-RA

Description

Product line RA is recommended for radiographic testing (RT), computed radiography (CR), and digital radiography (DR) in aerospace and energy industry.

Rod anodes of these X-ray tubes can be easily exchanged with standard transmission targets. Product line RA offers small diameters down to

Applications

Highlights

- Easy exchange of rod anodes with standard transmission targets

- Special solution for semiconductor industry – High Energy transmission rod anode available

- Automatic calibration for optimum performance

- Different target types for high flexibility

- Easy maintenance with adjusted ready-to-use click-in cathodes and automatic tube venting

- Long-term stability due to application of first-class components

- Unlimited lifetime

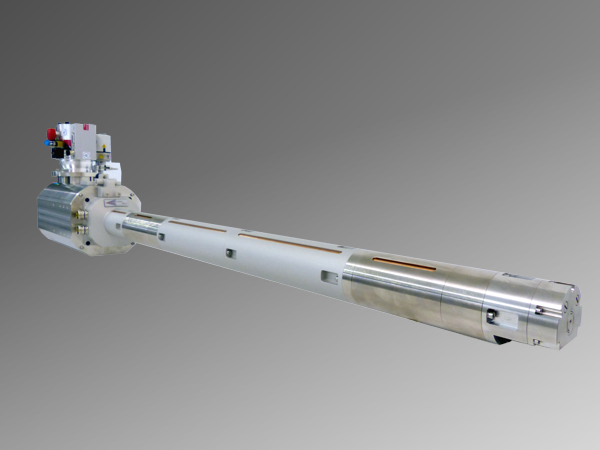

Product line RAC

Microfocus X-ray tube XWT-225-RAC

Description

Product line RAC is recommended for radiographic testing (RT), computed radiography (CR), and digital radiography (DR) in aerospace, energy, and railway industry.

These X-ray tubes provide an internal cooling of target and sealings and are available with a length up to

Applications

Highlights

- Internal cooling of target and sealings

- Full support of new standard

EN ISO 17636-2 - Flexible use for film (RT), computed radiography (CR), and digital radiography (DR)

- Automatic calibration for optimum performance

- Different target types for high flexibility

- Easy maintenance with adjusted ready-to-use click-in cathodes and automatic tube venting

- Unlimited lifetime

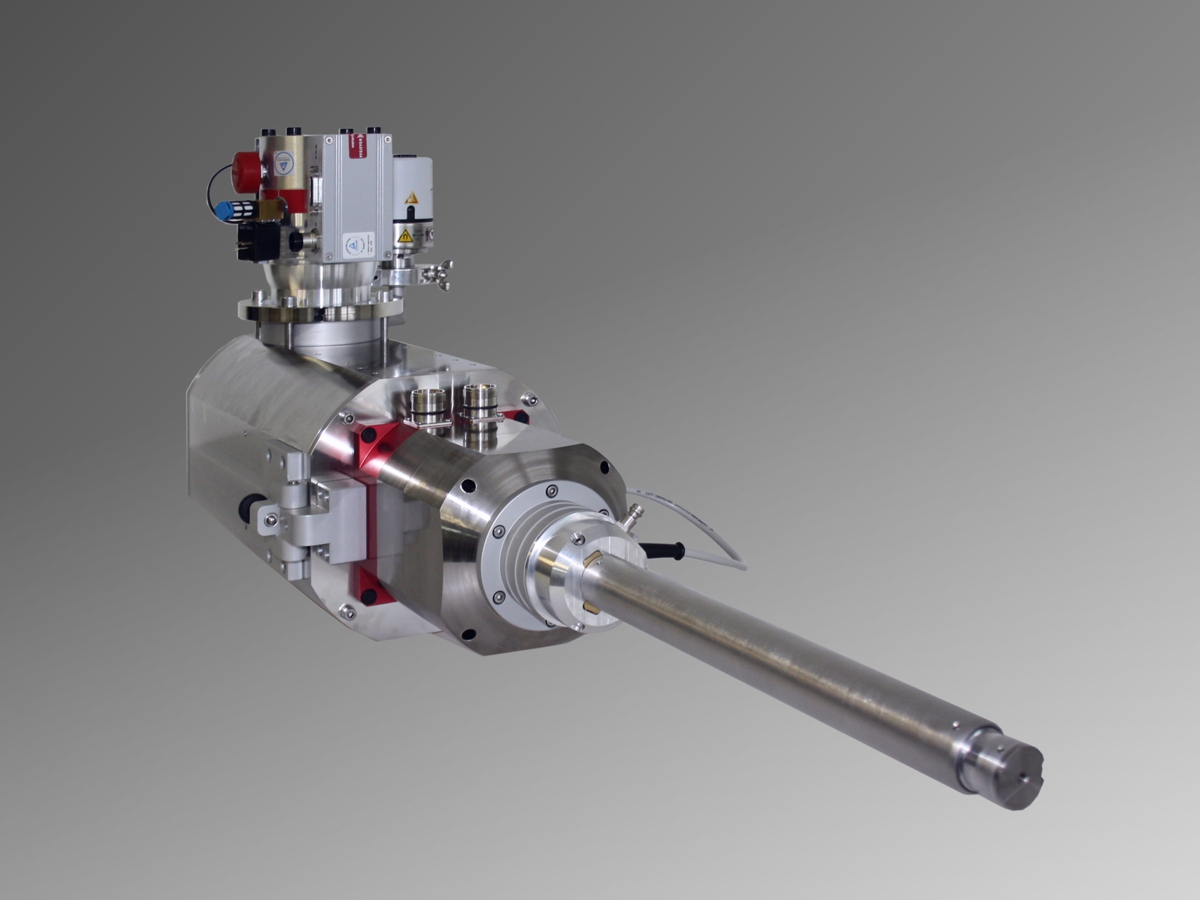

Product line RAC Superfocus

Microfocus X-ray tube XWT-225-RAC Superfocus

Description

High resolution rod anode tubes of product line RAC Superfocus are optimized for digital radiography (DR) applications. These X-ray tubes are recommended for radiographic testing (RT), computed radiography (CR), and digital radiography (DR) in aerospace and energy industry.

They feature an internal cooling of target and sealings; fully support the new standard

Applications

Highlights

- Internal cooling of target and sealings

- Full support of new standard

EN ISO 17636-2 - Flexible use for film (RT), computed radiography (CR), and digital radiography (DR)

- Automatic calibration for optimum performance

- Different target types for high flexibility

- Easy maintenance with adjusted ready-to-use click-in cathodes and automatic tube venting

- Unlimited lifetime

Applications for rod anode X-ray tubes

Radiographic testing (RT)

Radiographic testing (RT) is an imaging procedure of non-destructive testing to represent differences in material. The density of a test object is mapped to an X-ray film using an X-ray source. After processing the X-ray film, differences in material and defects can be identified.

Radiographic testing is applied in all areas of industry and specified by numerous codes and standards (

Computed radiography (CR)

Computed radiography (CR) with imaging plates is a digital imaging procedure, similar to the classical radiographic testing. Instead of X-ray film, a reusable phosphor imaging plate is used, that is read out by a scanner after exposure. The scanner generates a digital image of the radiographed object.

Computed radiography is used in all industries and is specified in numerous standards and codes (

Digital radiography (DR)

Digital radiography (DR) is the most recent imaging procedure of industrial radiography. It applies an electronic detector to capture the radiographic image. Using digital radiography the digital image of a test object is available in real-time and can be evaluated right after the exposure.

Digital detectors provide higher dynamics than X-ray film so that exposure times can be decreased. Often the magnification technique is used. Digital radiography of welds is described in the standard

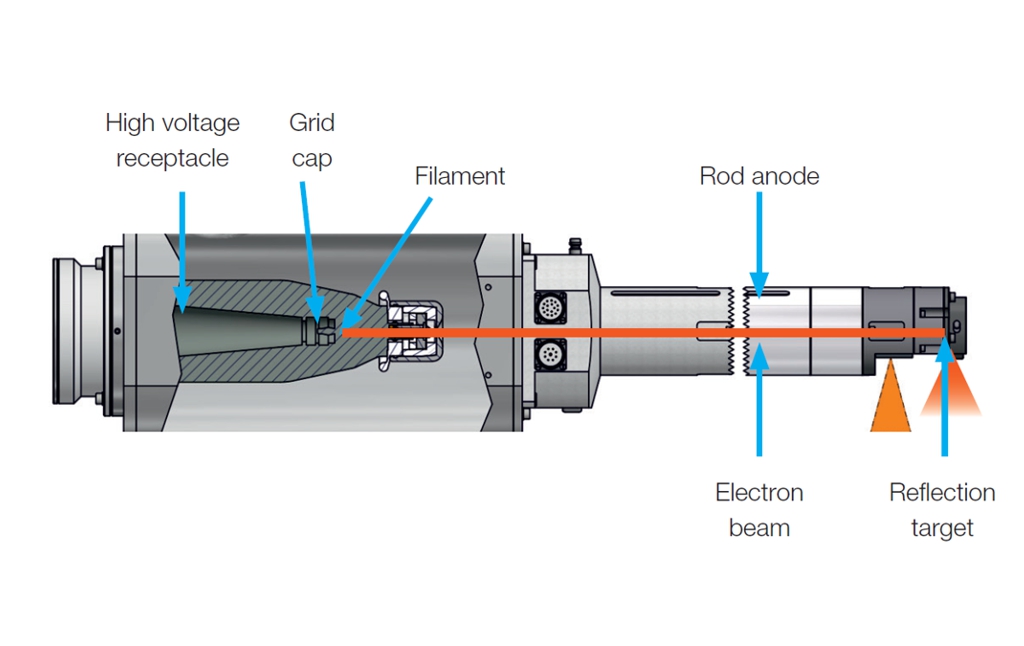

Technology of rod anode X-ray tubes

Cross section of microfocus rod anode X-ray tube

Advantages of rod anode X-ray tubes

-

- Detection of defects in areas that are difficult to access

- Positioning of the focal spot closer to the area of interest

- Higher resolution imaging, due to small focus

- Single wall penetration (Higher magnification, no information overlap)

- Support of new standards for digital radiography

Schematic illustration ot target types for rod anode tubes